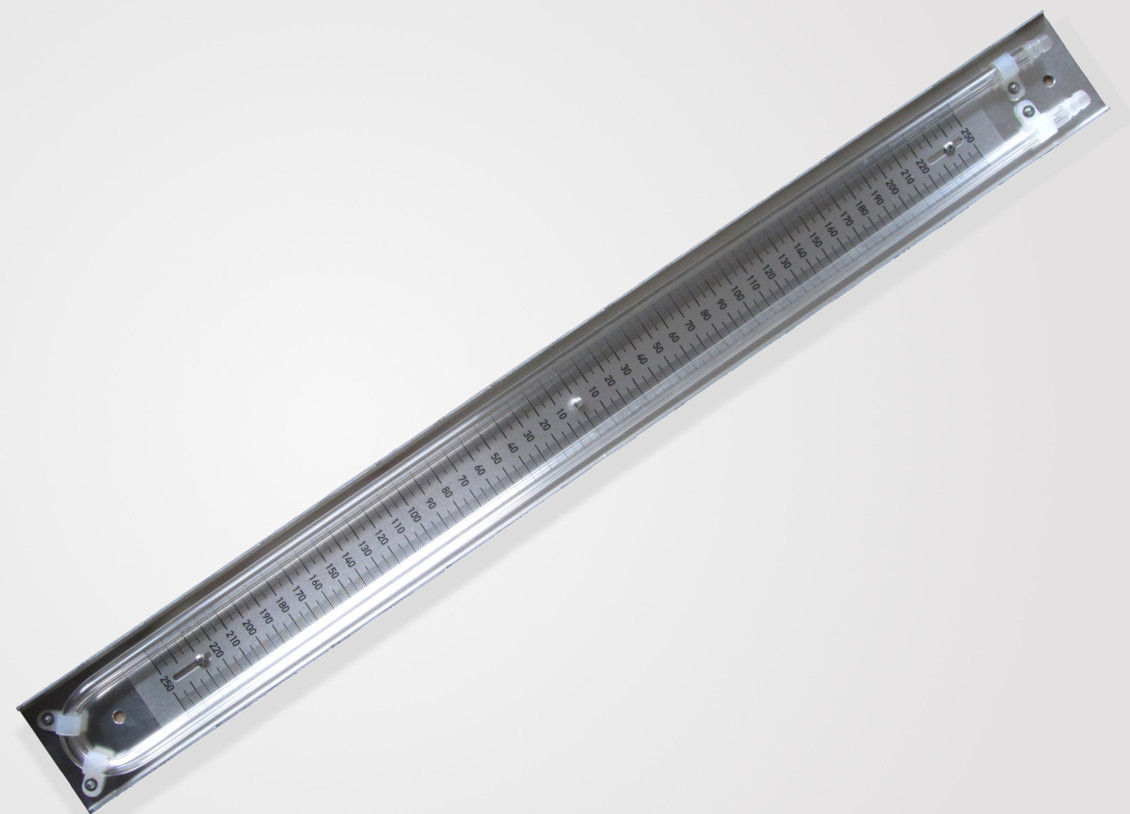

Differenzdruckgeber, Strömungswächter und Manometer

Präzision ist unsere

Leidenschaft

Dosch Messapparate GmbH Berlin. Ihr Spezialist und Partner in der Differenzdruck- und Durchflussmessung.

Unsere Produkthighlights

Referenzen

Wir sind überzeugt von dem, was wir tun. Vor allem aber sind wir stolz darauf, dass viele Kunden uns seit vielen Jahren die Treue halten.

Diese Firmen vertrauen uns:

Warum Dosch Messapparate?

Qualität

Wir fertigen hochwertige Produkte gemäß individueller Kundenanforderungen sowie nationaler und internationaler Standards. Gleichzeitig verpflichten wir uns zur kontinuierlichen Verbesserung unserer Produkte und Prozesse.

Service

Mit einer Vielzahl von erfahrenen Ingenieuren und Technikern stehen wir als verlässlicher Ansprechpartner für Sie bereit, auch nach der Auftragsabwicklung. Mit umfassender Beratung und persönlichem Service unterstützen wir Ihre Projekte und sorgen für eine lange Laufzeit Ihrer Anlagen.

Flexibilität

Wir können passgenaue Lösungen flexibel anbieten. Mit kurzen Entscheidungswegen, Fertigungsmöglichkeiten in kleinen sowie großen Stückzahlen, individueller Beratung und Lieferzeiten nach Wunsch setzen wir Ihre Wünsche um.

Partnerschaft

Wir sind Partner unserer Kunden und stehen ihnen beratend zur Seite. Gemeinsam finden wir die beste Lösung für die Messaufgaben in Ihren Anlagen.

News

Lassen Sie sich individuell beraten!

Dosch Messapparate GmbH

Kamenzer Damm 85

12249 Berlin

+49 30 7201530

vertrieb@dosch-gmbh.de