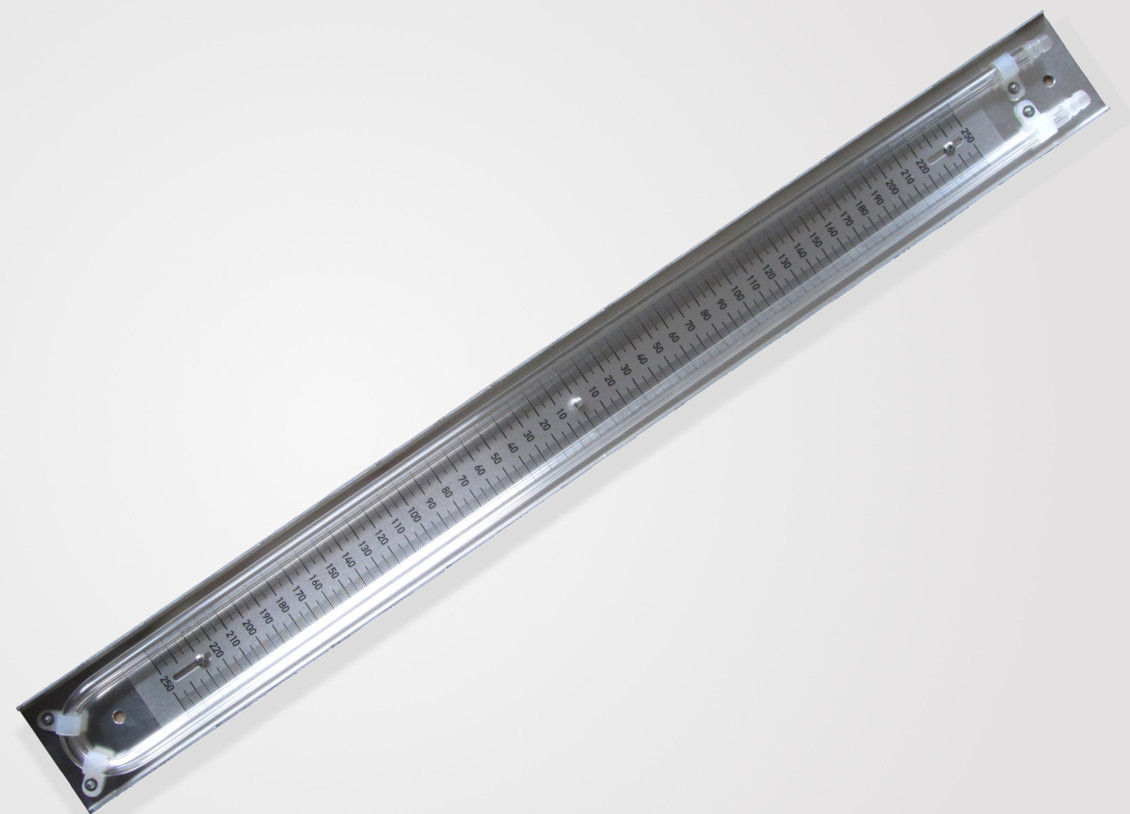

Differential pressure devices, flow switches, and pressure gauges

Precision is our

passion

Dosch Messapparate GmbH Berlin. Your specialist and partner in differential pressure and flow measurement.

Our product highlights

References

We are convinced of what we do. First and foremost, however, we are proud that many of our customers have remained faithful to us for so many years.

These companies trust us:

Why Dosch Messapparate?

Quality

We manufacture high-quality products according to individual customer requirements and in compliance with national and international standards. At the same time, we are committed to continuously improving our products and processes.

Service

We are a reliable point of contact for our customers. We support your project with comprehensive consulting and personal service, and ensure that your plant enjoys a long service life.

Flexibility

We can flexibly offer customized solutions. We implement your requirements with short decision-making paths, options for manufacturing both small and large quantities, individual consulting, and lead times to suit your needs.

Partnership

We are our customers’ partner and stand by their side ready to advise them. Together, we determine the best solution for measurement tasks in your plants.

News

Let us advise you individually!

Dosch Messapparate GmbH

Kamenz Dam 85

12249 Berlin

+49 30 7201530

vertrieb@dosch-gmbh.de