Venturi tube according to ISO 5167 for precise flow measurement

When it comes to precisely measuring the flow of aggressive and non-aggressive gases, vapours and liquids, a Venturi tube is an excellent choice. Venturis enable minimal pressure losses at high mass flows. The short inlet and outlet sections are particularly advantageous for this type of differential pressure sensor. From the oil and gas industry to the chemical industry, especially petrochemicals, or even in power stations, our flow meter in accordance with ISO 5167 are used. Due to their precise and reliable measurement, a Venturi flow meter is generally very popular in plant engineering.

In addition to other flow meter, Dosch Messapparate specialises in the manufacture of Venturi tubes and focuses on professional design in accordance with the requirements of ISO 5167. For example, after redefining the range of applications for turned Venturi tubes up to 350 millimetres in diameter, we adapted them within a short space of time.

We offer you customised Venturis in various designs. We will advise you in detail in advance. Our team then manufactures the tubes according to your requirements. Any diameter and the use of special materials, such as nickel-based alloys and plastics, are possible.

Put your trust in Dosch, the experts for precise measuring solutions, professional advice and customised requirements.

The advantages of Dosch venturis at a glance

-

Customised: In accordance with ISO 5167, there are three versions of Venturi tubes, which we adapt specifically to your systems and requirements.

-

Precise: Thanks to their precision in differential pressure measurement, Venturis ensure a long service life for the entire system.

-

Flexible: A Venturi tube is suitable for many different media and can be manufactured in different diameters.

-

Economical: The long-term accuracy and reliability of Dosch Venturi tubes lead to a reduction in operating costs and incorrect measurements.

Versions

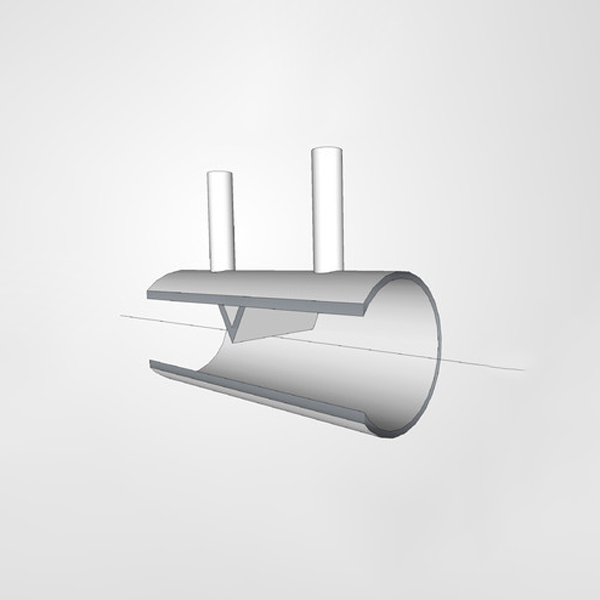

Venturi meters consist of an inlet cylinder, an inlet cone, to which the cylindrical neck section (throttle opening) and the outlet cone are connected. They can be designed either as a weld-in Venturi tube for high pressures or as a flanged-in flow measurement tube. According to the ISO 5167 calculation standard, Venturi tubes are divided into three types depending on how their inner surfaces are manufactured:

Venturi tubes with machined inlet cone

These precision flow tubes are particularly relevant for smaller nominal diameters (DN 50 to DN 250). The higher roughness requirements necessitate mechanical processing of the inner surface of the inlet cone. Depending on the application, the measurement uncertainty is in the range of 1% – 3% of the flow coefficient.

Venturi tubes with a rough inlet cone welded from sheet steel

Venturi tubes with a rough inlet cone welded from sheet steel are used for larger nominal diameters (DN 200 to DN 1200). As the influence of the pipe’s inner surface is less pronounced with larger nominal diameters, a more cost-effective sheet metal construction can be used here. Depending on the application, the measurement uncertainty is in the range of 1.5% – 3% of the flow coefficient.

Venturi tubes with grey cast iron inlet cone

Venturi meters with a grey cast iron inner profile offer the lowest measurement uncertainties and are suitable for a medium nominal diameter range (DN 100 to DN 800). Due to the more complex manufacturing process, these are recommended for particularly high measurement requirements. Depending on the application, the measurement uncertainty is in the range of 0.7% – 2.5% of the flow coefficient.

Venturi tubes for large-scale scientific experiment on fusion energy.

Find out how our flow restriction tubes were used for an ITER facility, a large-scale scientific experiment on the technological and scientific feasibility of fusion energy.

Matching accessories

We offer you the right products for Venturi tubes, such as pressure tapping nozzles

Pressure tapping nozzles

Typical versions of the pressure taps are

- Smooth nozzles for screw connections

- Welding nozzles

- Threaded nozzles

- Nozzles with flanges

Other accessories

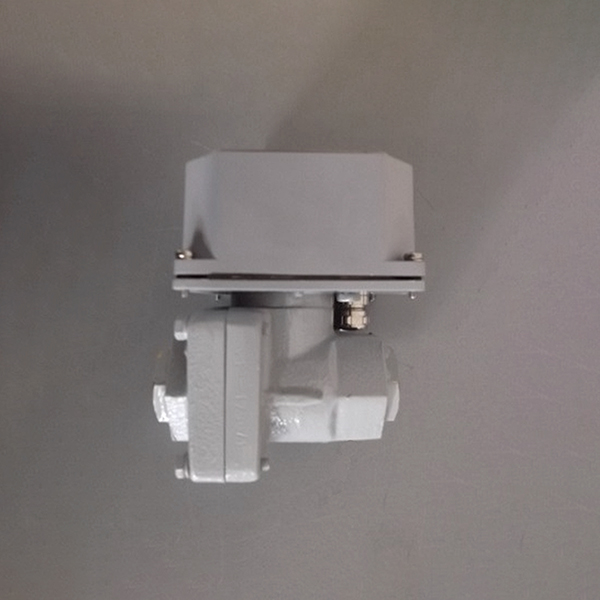

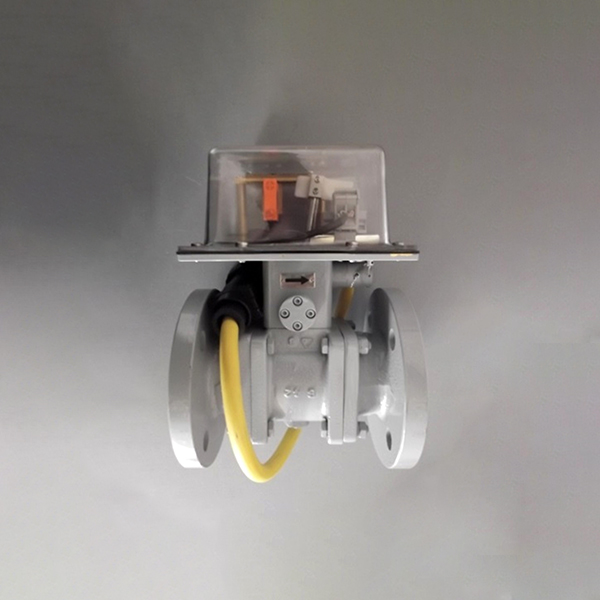

Venturi tubes can be fitted with shut-off valves and/or valve blocks. Condensate traps are recommended for vapour applications.

Do you have any questions? We will be happy to help you.

The basis for the Venturi effect is a channel, such as a pipe or a nozzle, on which an area is narrower. As soon as a fluid flows through the constriction, the Venturi effect occurs. The fluid can be either a liquid or a gas.

Using the example of a Venturi tube: At the narrowed point of the pipe, the flow velocity of the fluid increases while the pressure decreases at the same time. The fluid is pressed through the pipe at the constriction and this accelerates the flow. According to Bernoulli’s principle, which describes the relationship between velocity and pressure in a fluid, the increased flow velocity leads to a drop in pressure.

A Venturi tube and a Venturi nozzle are both instruments used in fluid mechanics to influence and measure the flow velocity of a medium. Despite their similar names and functions, however, there are differences. The main difference lies in the degree of cross-sectional constriction and the resulting effects on pressure loss and measurement accuracy. While the Venturi tube has a moderate constriction and focuses on a balanced ratio of pressure loss and accuracy, the Venturi nozzle offers higher measurement accuracy due to its greater constriction, but also a higher pressure loss.

Discover the Dosch Venturi nozzles.

The use of Venturi tubes according to the ISO 5167 standard offers several advantages, especially in the field of flow measurement of liquids, gases and vapours. ISO 5167 is an internationally recognised standard that provides guidelines for accurate flow measurement with differential pressure measuring devices. Here are some of the benefits of complying with this standard:

- Accuracy and reliability: ISO 5167 defines precise specifications for the design and installation of Venturi tubes. This ensures high accuracy and reliability in flow measurement. The standard takes into account various factors that can influence measurement accuracy, such as viscosity, temperature and pressure, and offers solutions to minimise these sources of error.

- Standardisation and global recognition: By complying with ISO 5167, companies can achieve consistent and comparable measurement results worldwide. This makes it easier to communicate and compare data between different systems and organisations. Compliance with international standards ensures that measurement systems and components are compatible, which facilitates integration into existing systems. Using devices manufactured in accordance with ISO 5167 can increase the confidence of regulatory authorities and customers in measurement accuracy and process quality.

- Simplicity of installation and maintenance: The standard provides clear instructions for installation and maintenance, which reduces the effort required for operation and maintenance.

- Cost-effectiveness: Although the initial costs of complying with the standard may be higher, the long-term accuracy and reliability lead to a reduction in operating costs and incorrect measurements.

Similar products

- Alle

- Accessories

- Differential pressure devices

- Flow switches

- Pressure, temperature, and humidity measurement

- Product highlight

Let us advise you individually!

Dosch Messapparate GmbH

Kamenz Dam 85

12249 Berlin

+49 30 7201530

vertrieb@dosch-gmbh.de