Meter runs

Application

Meter runs combine primary elements with an inlet and outlet section and thus ensure low-interference flow measurement of aggressive and non-aggressive gases, vapors and liquids. They are mainly used in small pipelines, as this is where the influence of disturbances is greatest.

Designs

We offer meter runs in numerous designs. We will be happy to assist you in choosing the most suitable design. The meter runs are completely assembled and delivered ready for installation. Optionally for flange mounting or welding.

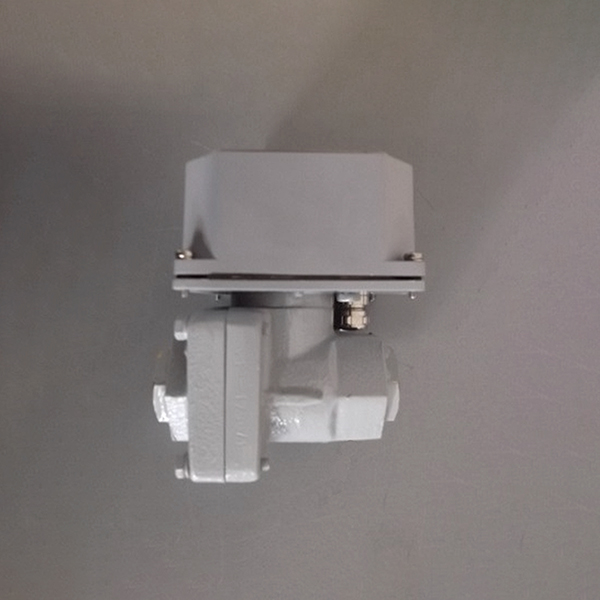

Meter runs type 94D

Our standard for flow measurement in small pipelines, based on a ring chamber orifice plate with replaceable measuring insert. The inlet and outlet pipes form a unit with the ring chamber’s socket rings and are brought right up to the measuring disc without any attachment. In this way, any interference can be minimised as best as possible.

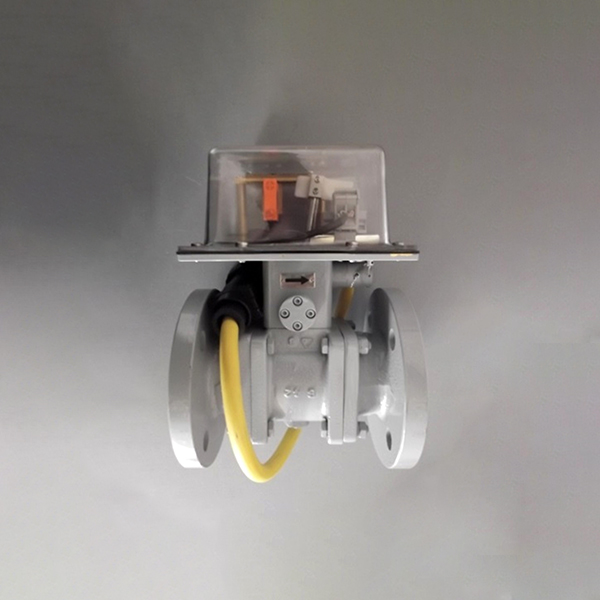

Meter runs type 94F

With type 94F, any primary element can be flanged into the meter run. The differential pressure is taken via the pressure taps in the inlet and outlet. This design is also suitable for larger pipelines.

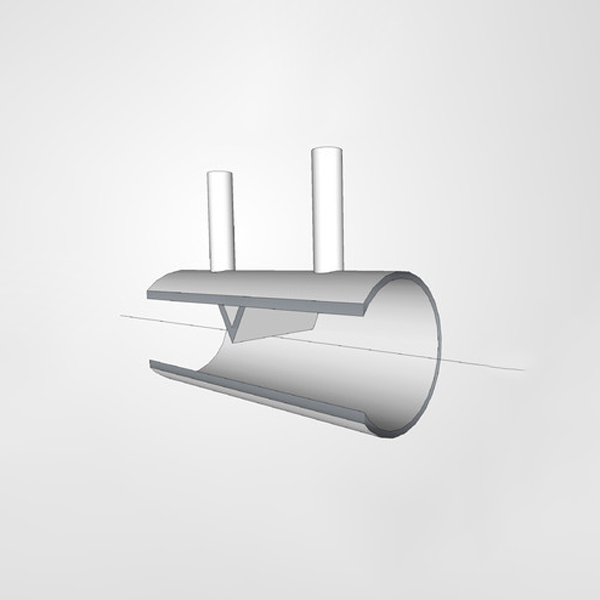

Meter runs type 94M

The type 94M corresponds to meter runs with a flanged-in orifice plate between orifice flanges (e.g. according to DIN 19214 or ASME B16.36). Here the advantages of an orifice plate are combined with the advantages of the meter run.

Siehe SteckblendenFurther product information

Pressure tap

Typical versions of the pressure taps are:

- Smooth fittings for threaded connections

- Welded fittings

- Threaded fittings

- Sockets with flanges

- according to DIN EN 61518 (compact)

Measurement uncertainty

Depending on the application, the measurement uncertainty is approx. 0.5% – 1.5% of the flow coefficient.

Equipment

Meter runs can be equipped with shut-off valves and/or valve blocks. Condensate vessels are recommended for steam applications.

Similar products

- All

- Accessories

- Differential pressure devices

- Flow switches

- Pressure, temperature, and humidity measurement

Let us advise you individually!

Dosch Messapparate GmbH

Kamenz Dam 85

12249 Berlin

+49 30 7201530

vertrieb@dosch-gmbh.de