Orifice plate according to ISO 5167 – Your reliable and cost-effective choice for flow measurement

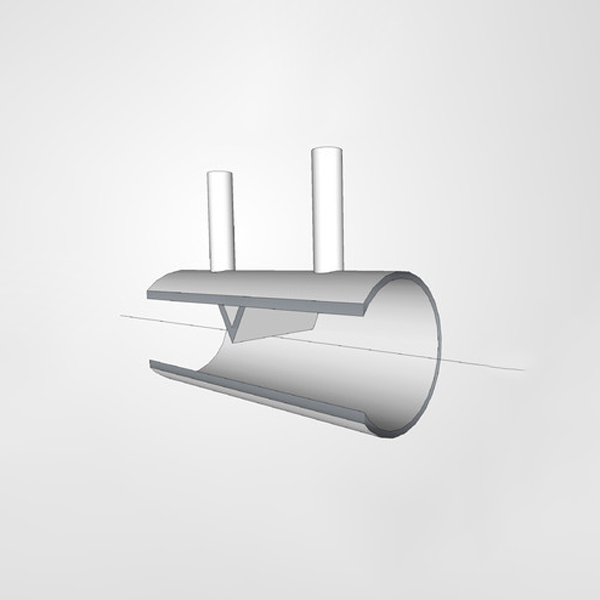

Rely on orifice plates according to ISO 5167 for precise flow measurement of fluids in pipelines. An orifice plate is characterized by its sharp-edged inlet, generating a defined differential pressure used to calculate the volumetric or mass flow rate. The orifice plate coefficient of discharge accounts for all losses that occur when a fluid passes through the plate. Thanks to their standardization based on the ISO 5167 standard, our orifice plates offer accurate and reproducible measurements, as well as easy comparability and interchangeability. Our standard orifice plate is a 65mm orifice plate.

Whether for process monitoring, energy optimization, flow metering, or ensuring process stability through precise flow control – a Dosch orifice plate is your reliable and economical solution. Trust in our quality and precision!

Advantages of Dosch orifice plates

-

High Precision: Our orifice plates according to ISO 5167 ensure accurate flow measurements.

-

Cost-Effective Solution: An orifice plate is a popular, economical choice for flow measurement of fluids in pipelines.

-

Customizable: Our orifice plates are tailored exactly to your requirements.

-

Decades of Experience: Benefit from our long-standing expertise for the highest quality.

-

Reliable Availability: We ensure reliability thanks to experienced manufacturing and high production capacity.

Possible Versions

Experience the right solutions for precise and reliable flow measurement of fluids in pipelines with our three different versions. We offer a standard orifice plate with single tapping, a ring chamber orifice plate, a orifice plate corner tapping, and a weld-in orifice plate. Our orifice plates are highly flexible and can be customized with additional tappings for redundant measurements or for use at high/low temperatures and high pressure.

Explore our versions now or get in touch for personal advice!

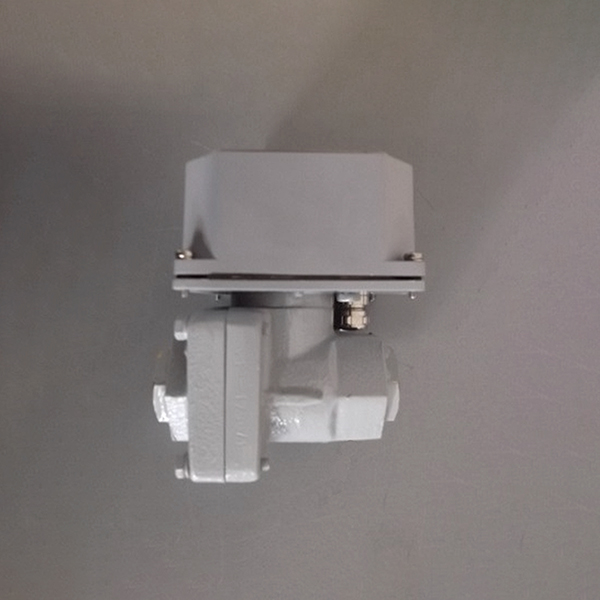

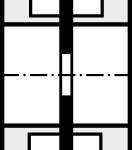

Standard orifice plate with single bore BLB 300

One-piece mounting ring with non-replaceable measuring insert. The easy-to-clean individual bores are particularly advantageous for media that resinify or build up, or for systems that do not remain in operation continuously.

Brochure

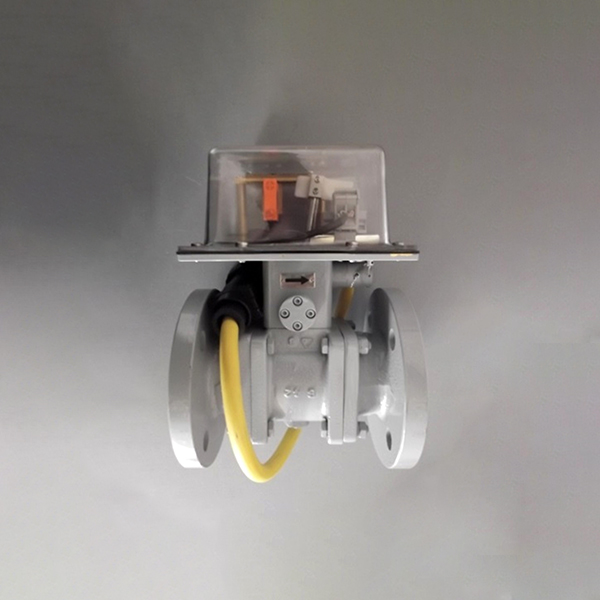

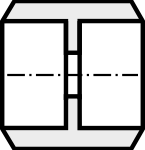

Ring Chamber Orifice BLA 200

Two-piece frame ring with ring chamber removal and exchangeable measuring insert. The ring chamber removal creates a good average value of the plus and minus pressure. This produces a smoother measuring signal. This generates a quieter measurement signal.

Brochure

Welding plug EBLB 800 / EBLA 800

Standard orifice plates – whether with annular chamber (EBLA 800) or without (EBLB 800) – can also be offered as weld-in differential pressure devices. These are used in the high-pressure and high-temperature range.

We are happy to expand the weld-in orifice plate with a welded-on inlet and outlet pipe to meet the requirements of the calculation standard.

BrochureTypical areas of application of our orifice plate

Always ready for use across various industries: Our orifice plates are widely used wherever precise flow measurements are required. In the energy industry, they measure steam, water, and gas flows for efficiency monitoring, while an orifice plate monitors crude oil and gas flows in the oil and gas industry. They are also indispensable in the chemical and petrochemical industries, as well as in water and wastewater management. In the pharmaceutical and food industries, they are used to monitor hygienic processes.

Orifice plates for Total Refinery Central Germany

Learn how Dosch orifice plates were successfully used in the 150 million-euro project “Proturn2020”.

Matching accessories

Pressure tap

Typical versions of the pressure nozzles are:

- smooth sockets for screw connections

- Welding socket

- Threaded socket

- Sockets with flanges

- according to DIN EN 61518 (compact)

Measurement uncertainty

Depending on the application, the measurement uncertainty is approx. 0.5% – 1.2% of the flow coefficient.

Equipment

Standard orifices can be equipped with shut-off valves and/or valve blocks. Condensate vessels are recommended for steam applications.

Do you have any questions? We will be happy to help you.

The product is the same, it’s just a different term.

Orifice Plates according to ISO 5167 are classic measuring plates with a sharp-edged inlet. They are used for flow measurement of fluids in pipelines and generate a differential pressure, which is then used to calculate the volumetric or mass flow rate.

In comparison, restriction orifice plates are also manufactured according to ISO 5167 and other standards. However, they create a fixed pressure drop or restrict the mass flow, without directly measuring the flow itself.

Insertion plates (BLS 100) are used for flow measurement of gases, vapors, and liquids, particularly in large pipelines. They are designed as measuring plates and can be configured as orifice plates depending on the process conditions. These plates feature a handle shield and are directly installed between pipeline flanges or measuring flanges.

Yes, orifice plates are ISO plates and are calculated and manufactured according to DIN EN ISO 5167. Other standards include ISO TR 15377, ASME MFC-14M, and AGA3. We are happy to advise you on this!

The required inlet and outlet sections are regulated by ISO 5167 and depend on the installation disturbance upstream of the orifice plate as well as the diameter ratio of the throttle opening. These pipe sections are generally long, but there are ways to shorten them, such as by using flow straighteners, flow shapers, or multi-orifice plates. Additionally, there are calculation tools that help determine the measurement uncertainty for short pipe sections.

For orifice plates is the term “uncertainty” used. This indicates how precise the measurement is and within which range the true value is likely to fall. The measurement uncertainty for orifice plates is between 0.5% and 0.75%, depending on the diameter ratio and manufacturing quality. Proper installation according to standards also significantly impacts accuracy.

Orifice plates according to ISO 5167 are used in many industries, particularly in areas where precise flow measurements are required. Orifice plates are used in the following fields:

- Energy industry: For measuring steam, water, and gas flow in power plants for efficiency monitoring.

- Oil and gas industry: For monitoring and controlling crude oil, natural gas, and process gas flows.

- Chemical and petrochemical industries: For precise measurement of liquids and gases in production processes.

- Water and wastewater management: For controlling water flows in supply and treatment plants.

- Pharmaceutical and food industries: For monitoring hygienic processes with liquids and gases.

Similar products

- Alle

- Accessories

- Differential pressure devices

- Flow switches

- Pressure, temperature, and humidity measurement

- Product highlight

Let us advise you individually!

Dosch Messapparate GmbH

Kamenz Dam 85

12249 Berlin

+49 30 7201530

vertrieb@dosch-gmbh.de