Averaging pitot tube

Application

Averaging pitot tube are primary elements for measuring the flow of gases, steams, and fluids. Compared to differential pressure devices in accordance with ISO 5167, their benefits are their very low pressure losses and very flexible installation options.

Designs

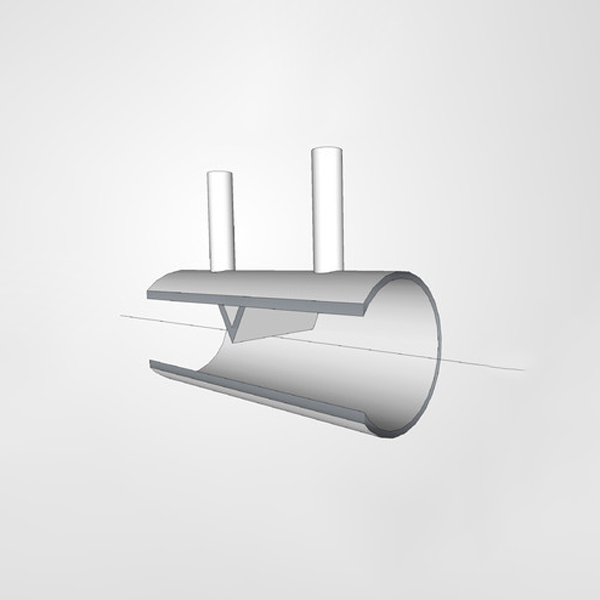

Pitot tubes operate on a similar principle to differential pressure elements to ISO 5167. The tube projects into the pipeline and is divided into two pressure chambers (upstream and downstream), each with several pressure tapping holes. On the upstream side the total pressure is applied, on the downstream side a negative pressure is generated. The pressure difference is measured by a differential pressure device outside the pipeline and thus the flow rate is determined. The pressure holes distributed over the flow cross-section give a good averaging of the pressure signal. This reduces the requirement for a uniform flow profile, i.e. the required length of the stilling section.

Further product information

Differential pressure tapping

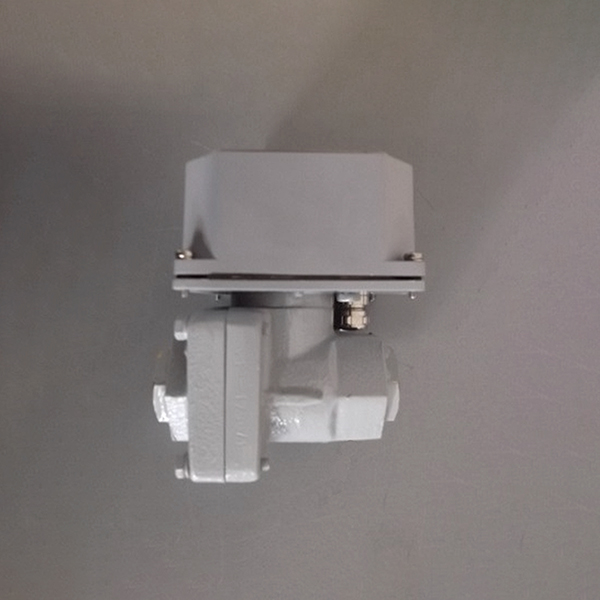

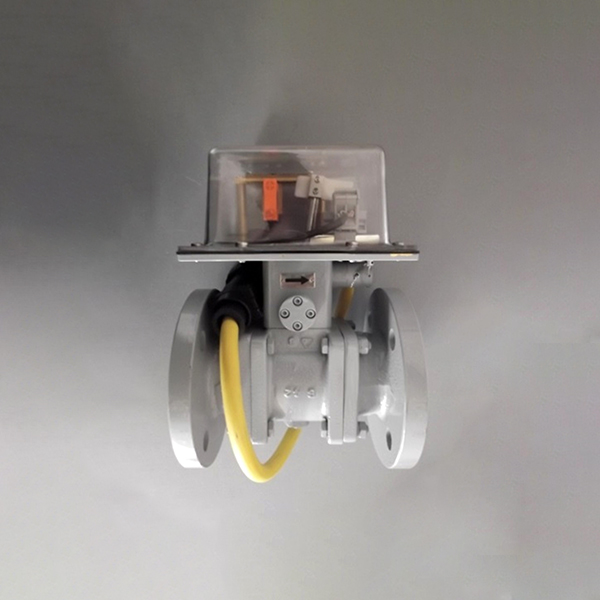

Typical pressure tapping fitting designs are:

- Threaded fittings

- Smooth fittings for threaded connections

- Welded fittings

- Flange plate for directly mounting a valve block

Measurement uncertainty

The measurement uncertainty is approx. 1% of the measured signal.

Further information

Feel free to contact us for further information and concrete inquiries!

Similar products

- All

- Accessories

- Differential pressure devices

- Flow switches

- Pressure, temperature, and humidity measurement

Let us advise you individually!

Dosch Messapparate GmbH

Kamenz Dam 85

12249 Berlin

+49 30 7201530

vertrieb@dosch-gmbh.de