U-tube manometers – easily visualize pressure differences without power supply

Rely on proven precision in pressure measurement with a U-tube manometer from Dosch. This type of pressure gauge/ differential pressure gauge makes pressure differences visible in a U-shaped tube filled with liquid. It operates without any external power source and delivers reliable measurement results. Especially in laboratories and industrial applications, such pressure gauges are indispensable.

Whether you need a single unit or a larger quantity – send us a non-binding inquiry or explore more details about our U-tube manometers!

Advantages of Dosch U-tube manometer

-

Precise measurement: We ensure high accuracy in measuring the pressure of gases and liquids.

-

Extremely durable: Robust materials and high-quality craftsmanship ensure a long service life.

-

Versatile use: Our differential U-tube manometers are suitable for a wide range of applications.

Versions

Our U-tube manometers are designed for measuring ranges from 20 mbar to 300 mbar – with measuring lengths of up to 3 meters. They are suitable for pressure, vacuum, and differential pressure measurements and are ideal for harsh operating conditions thanks to a robust aluminum base plate and an acrylic U-tube. Even at higher temperatures (up to 80 °C) or in humid environments, they remain precise and reliable.

The most commonly used filling liquids are:

- Density 1.0 kg/dm³: Water or “Delalk blue” measuring liquid, frost-resistant

- Density 1.92 kg/dm³: Green Teflon oil, practically non-evaporating

Feel free to send us an inquiry for additional U-tube manometers in various configurations.

Typical applications of our U-tube manometers

Use Dosch U-tube manometers for a wide range of applications. They are a reliable choice for pressure, vacuum, and flow measurements in the chemical and process industries, as well as for calibrating pressure sensors in laboratories. Our liquid manometers and U-tube manometers for gas pressure are designed to meet demanding requirements:

Do you have any questions? We will be happy to help you.

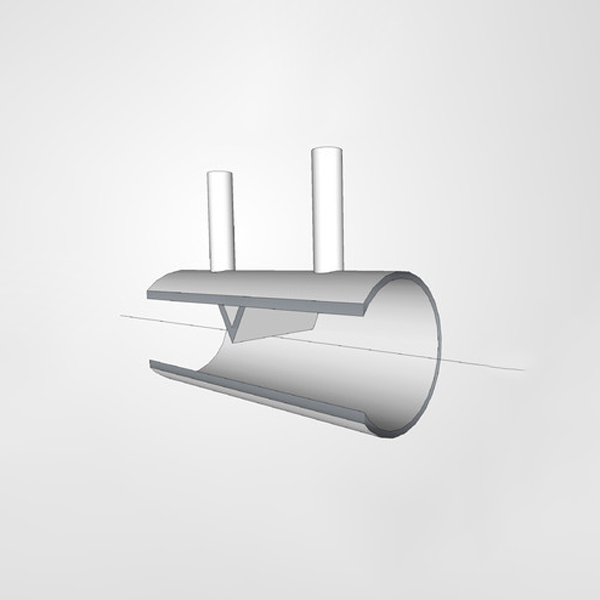

A U-tube manometer measures pressure by comparing the height of a liquid column in a U-shaped tube. When pressure is applied to one side, the liquid level changes. The difference in height between the two columns shows the pressure difference. The higher the pressure, the greater the displacement. It’s a simple, accurate, and power-free method to measure gas or liquid pressure.

Differential U-tube manometers from Dosch are highly reliable pressure measuring instruments for gas and liquid applications. The accuracy of a liquid manometer depends on several factors, such as scale readability, the properties of the measuring liquid, and environmental influences at the installation site.

Thanks to a sturdy aluminum base plate (2 mm thick) and an acrylic U-tube, our U-tube differential manometers are especially suitable for rough operating conditions and can withstand temperatures up to 80 °C and high humidity.

Considering these factors, the high-quality U-tube manometers from Dosch offer an accuracy better than 1 percent – making them a robust, highly reliable solution for precise pressure measurements. Since the device relies on the physical measurement of fluid level differences, it does not require electronic calibration and is particularly low-maintenance.

As a pressure measuring device, a U-tube manometer operates with various measuring fluids selected based on density, viscosity, and temperature resistance. The most common fillings include:

- Water or “Delalk blue” measuring liquid (frost-resistant, density 1.0 kg/dm³)

- Green Teflon oil (virtually non-evaporating, density 1.92 kg/dm³)

In principle, all liquids with a density of 1.0 kg/dm³ can be used with a Dosch U-tube manometer, as long as they are chemically compatible with the materials used in the device and suitable for the application. The choice of liquid depends on the desired measuring range and environmental conditions. The higher the density, the more sensitive the manometer is to small pressure changes.

Maintaining a U-tube manometer is straightforward, but essential to ensure long-term precision. Key maintenance steps include:

- Cleaning the U-tube: Deposits can affect readability. Clean by flushing with mild detergent and rinse with distilled water to avoid residue.

- Checking the fluid level: The correct fill level is essential for accurate measurements. Refill or replace evaporated or contaminated fluid regularly.

- Removing air bubbles: Air bubbles can distort readings. Tap the tube gently or tilt the device to remove them.

Inspecting seals and fittings: In industrial settings, seals should be checked regularly to prevent leaks.

As a differential pressure gauge, the U-tube manometer is highly versatile and used in various industries for pressure, vacuum, and differential pressure measurements. It is particularly well suited for measuring low pressures, draft levels, and basic gas flow rates. Typical areas of use include:

- Laboratories: Measures pressure differences between two points with high precision – ideal for gas and liquid pressure experiments and sensor calibration.

- Industry: Suitable for measuring gas pressure and flow in HVAC systems and industrial processes – especially in chemical, food, and pharmaceutical sectors.

- HVAC (Heating, Ventilation, and Air Conditioning): Used to monitor air pressure in ventilation and heating systems.

Education & Training: Perfect for demonstrating physical pressure principles in schools and universities – operates without power and offers a clear visual representation.

Similar products

- Alle

- Accessories

- Differential pressure devices

- Flow switches

- Pressure, temperature, and humidity measurement

- Product highlight

Let us advise you individually!

Dosch Messapparate GmbH

Kamenz Dam 85

12249 Berlin

+49 30 7201530

vertrieb@dosch-gmbh.de