Standard orifices

Application

A distinction is made between flange pressure tapping and pipeline tapping. In each case, pressure tapping is carried out a defined distance away from the orifice plate. In special cases, differential pressure tapping can also be carried out as standard-like corner tapping in the flange.

Designs

Three versions of the standard orifice plate are distinguished:

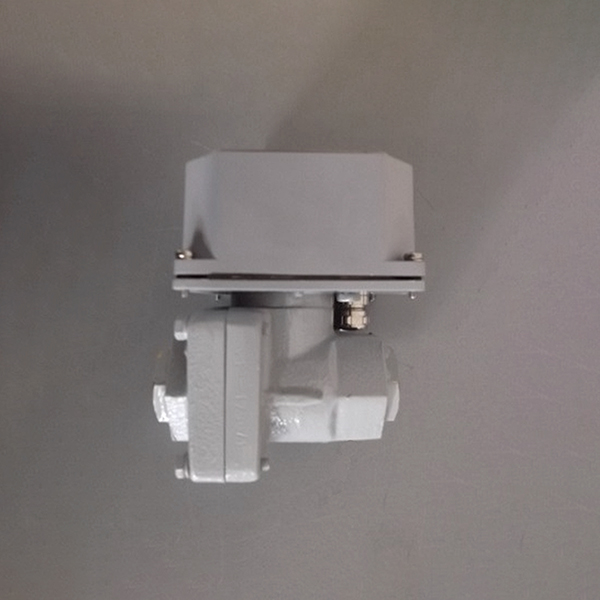

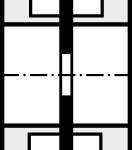

Standard orifice plate with single bore BLB 300

One-piece mounting ring with non-replaceable measuring insert. The easy-to-clean individual bores are particularly advantageous for media that resinify or build up, or for systems that do not remain in operation continuously.

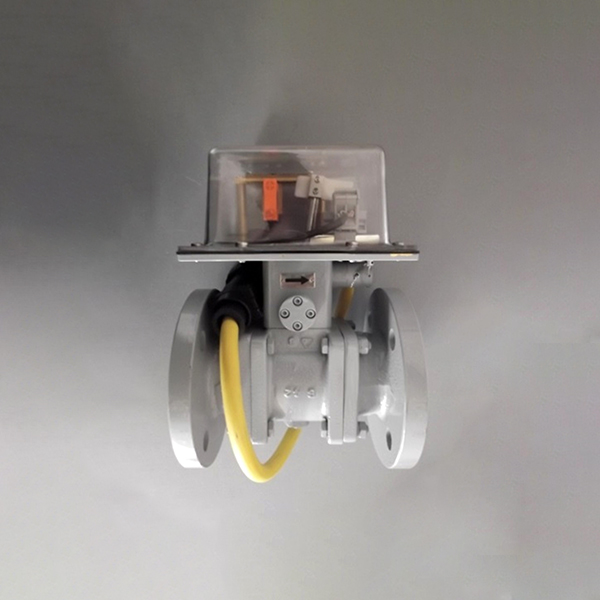

Ring Chamber Orifice BLA 200

Two-piece frame ring with ring chamber removal and exchangeable measuring insert. The ring chamber removal creates a good average value of the plus and minus pressure. This produces a smoother measuring signal.

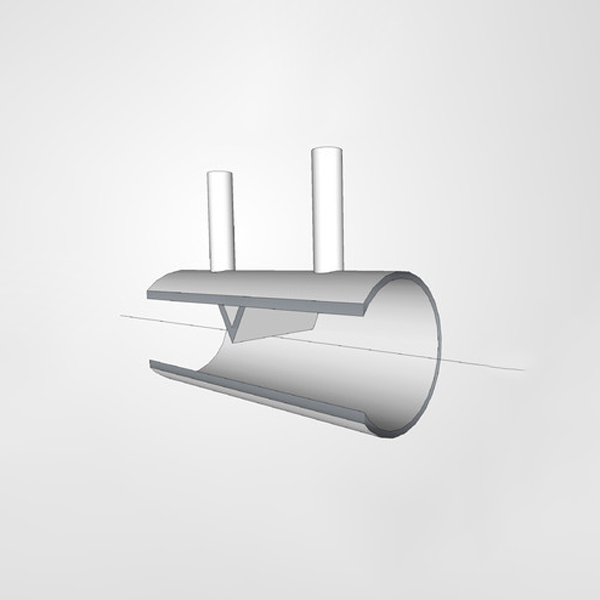

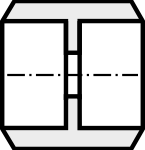

Welding plug EBLB 800 / EBLA 800

Standard orifice plates – whether with annular chamber (EBLA 800) or without (EBLB 800) – can also be offered as weld-in differential pressure devices. These are used in the high-pressure and high-temperature range.

We are happy to expand the weld-in orifice plate with a welded-on inlet and outlet pipe to meet the requirements of the calculation standard.

Further product information

Pressure tap

Typical versions of the pressure taps are:

- Smooth fittings for threaded connections

- Welded fittings

- Threaded fittings

- Sockets with flanges

- according to DIN EN 61518 (compact)

Measurement uncertainty

Depending on the application, the measurement uncertainty is approx. 0.5% – 1.2% of the flow coefficient.

Welded variants

Weld-in standard orifice plate EBLB 800 / EBLA 800

Standard orifices – be it with ring chamber (EBLA 800) or without (EBLB 800) – can also be offered as weld-in differential pressure elements. These are used in the high-pressure and high-temperature range.

We would be happy to expand the weld-in panel with a welded-on inlet and outlet pipe in order to meet the requirements of the calculation standard.

Equipment

Standard orifices can be equipped with shut-off valves and/or valve blocks. Condensate vessels are recommended for steam applications.

Similar products

- All

- Accessories

- Differential pressure devices

- Flow switches

- Pressure, temperature, and humidity measurement

Let us advise you individually!

Dosch Messapparate GmbH

Kamenz Dam 85

12249 Berlin

+49 30 7201530

vertrieb@dosch-gmbh.de