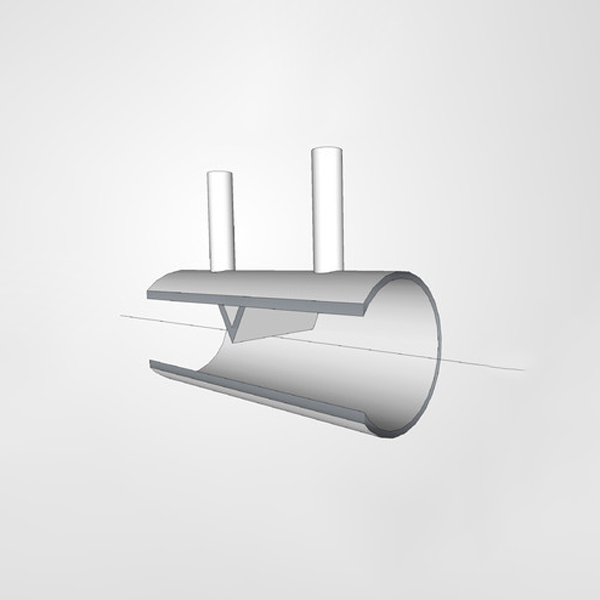

Insertion plates

Application

Orifice plates BLS 100 are used to measure the flow of aggressive and non-aggressive gases, vapors and liquids, especially in large pipelines.

Further product information

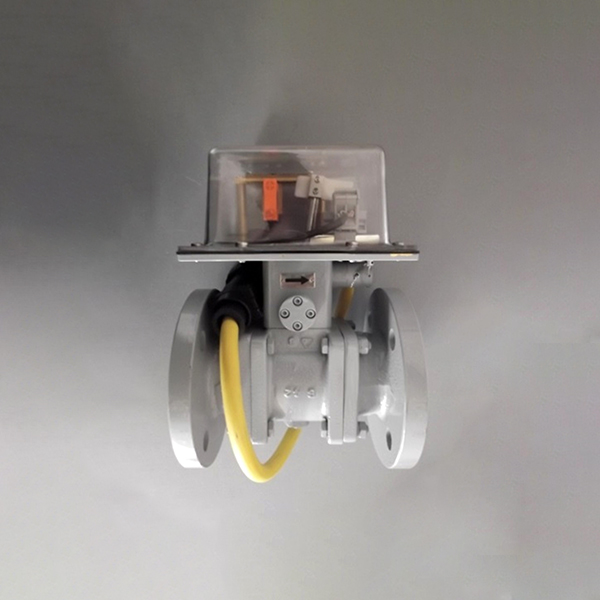

Differential pressure tapping

A distinction is made between flange pressure tapping and pipeline tapping. The pressure is tapped at a defined distance from the panel. In special cases, the effective pressure can also be tapped in a standard-like manner as a corner tapping in the flange.

Would you like a complete package consisting of an orifice plate, differential pressure tapping and an inlet and outlet section? Then we recommend our meter runs !

Measurement uncertainty

Depending on the application, the measurement uncertainty is approx. 0.5% – 1.2% of the flow coefficient.

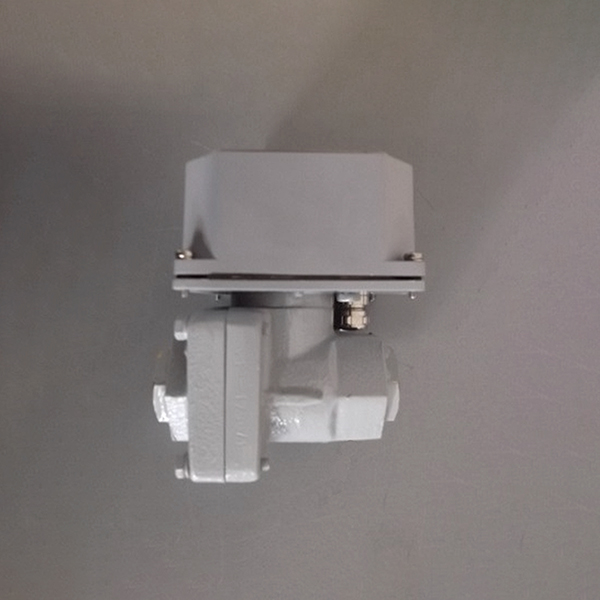

Orifice flanges

Orifice flanges are flanges specially developed for flow measurement based on the differential pressure principle. The pressures are tapped through a hole in the flange at a defined distance before and after the orifice plate. Orifice flanges are manufactured according to ASME B 16.36 or DIN 19214 as standard. Other standards (e.g. NORSOK, JIS) can also be considered.

Equipment

We would also be happy to supply you with the required orifice flanges, which already contain the pressure tapping lines.

Similar products

- All

- Accessories

- Differential pressure devices

- Flow switches

- Pressure, temperature, and humidity measurement

Let us advise you individually!

Dosch Messapparate GmbH

Kamenz Dam 85

12249 Berlin

+49 30 7201530

vertrieb@dosch-gmbh.de